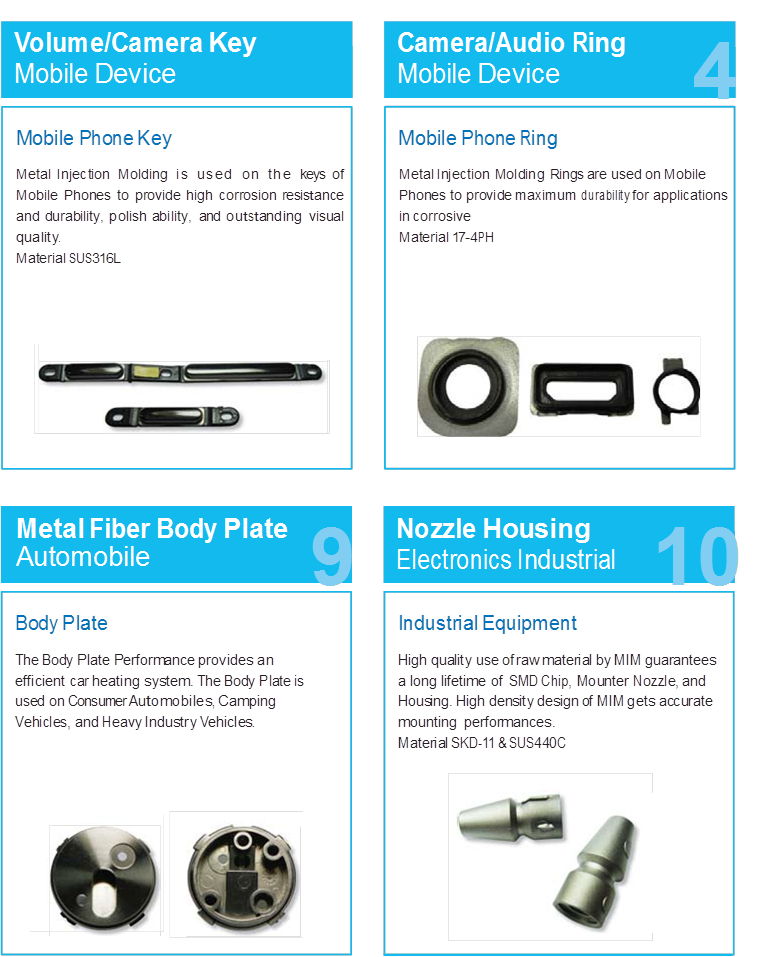

Amphenol MCP produces high quality parts with over 90% metal density through our metal injection molding (MIM) process. The MIM process provides greater flexibility in design complexity, prevents corrosion, and provides a resistant polish. It allows us to produce large runs with a very low material waste. The MIM process is used on components of various applications including mobile phones, laptops, and industrial and automotive platforms.

In-house Tooling:

- Capacity: 20 to 24 sets per month

- Prototype Tool (Single Cavity): 7 ~ 10 days (Samples: 2 ~ 4 days)

- Mass Production Tool: 15 ~ 17 days (Samples: 5 days)

- Ramp up Lead Time: 2 weeks (Mobile Phone Hinge Cam: after 2~3 samples

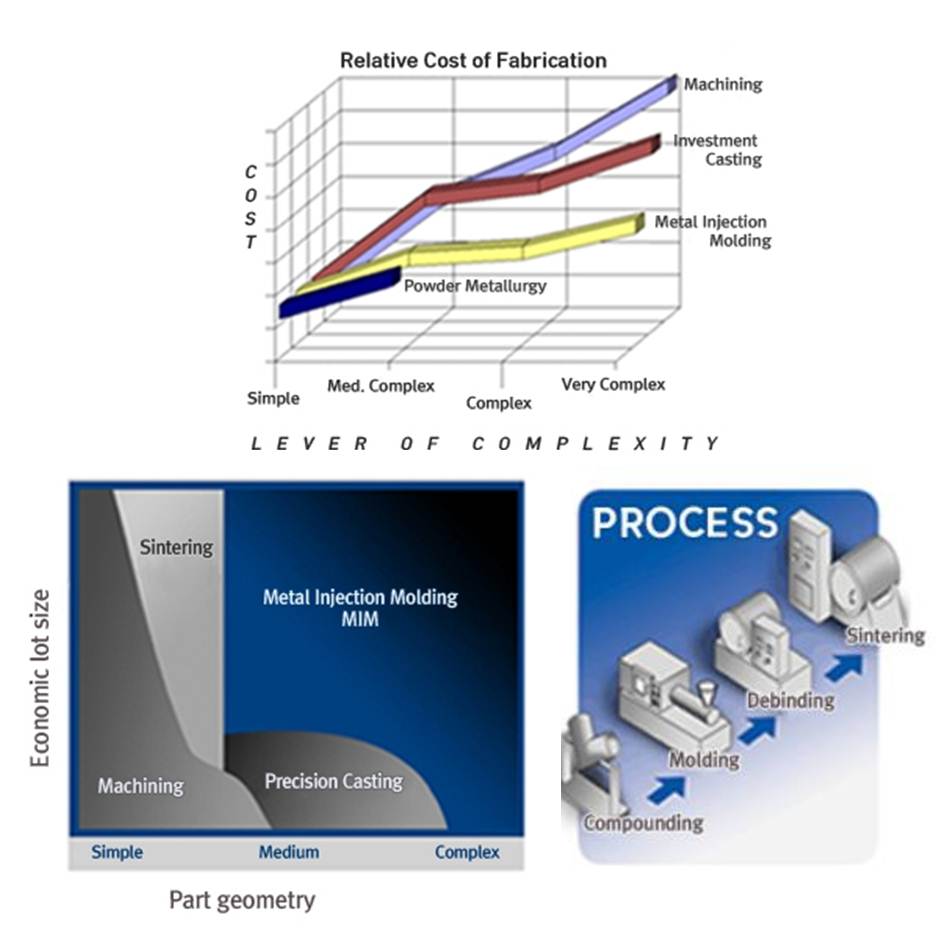

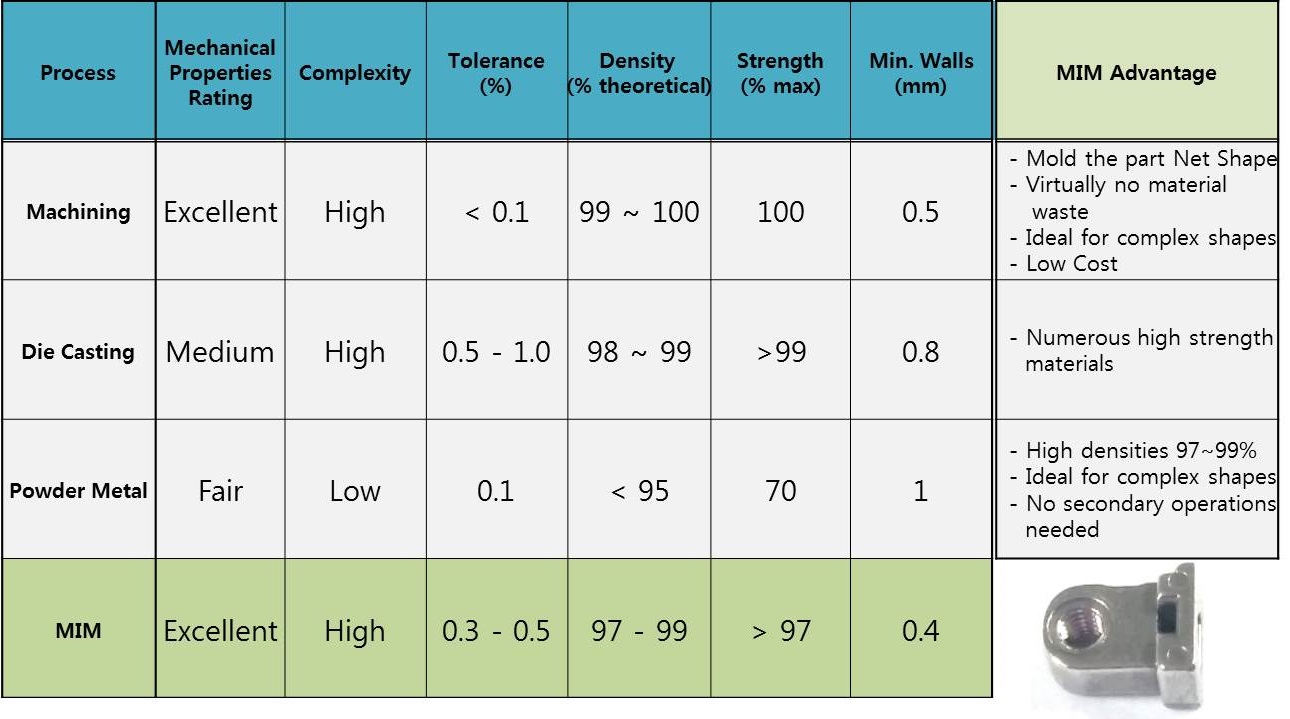

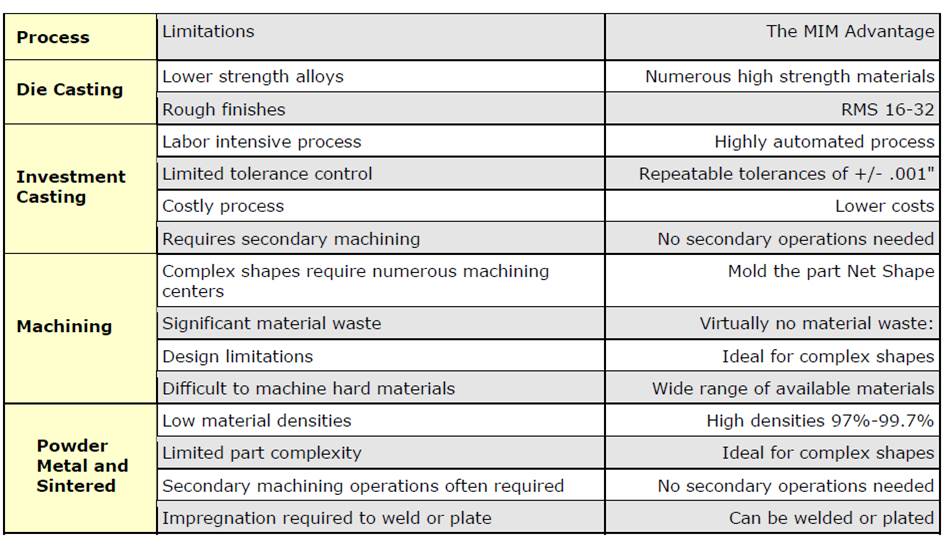

Comparison of MIM to other Processes:

Visit our Metal Injection Molding – MIM divisions

Amphenol MCP Korea LTD (MCPK)

www.amphenolmcpkorea.com

Amphenol Hangzhou Phoenix (HZP)

www.amphenol-hzp.com